Bunger-Henry 256 laboratory

Introduction

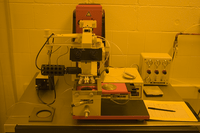

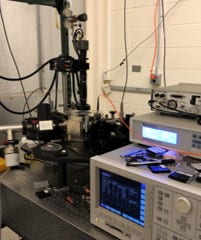

The Bunger-Henry 256 lab is a class-1,000 clean room with a class-100 soft wall modular clean room in one corner. The room adjoining the clean room serves as a measurement room. This area is currently a home to several semiconductor characterization systems for optoelectronic research. Fully functional as of April 2006, the BH 256 lab is equipped with a contact photolithography system, a high-vacuum electron-gun and thermal evaporator, a rapid thermal annealing system, wet chemical benches, etc. While this lab serves as an interim for our group until the completion of the IEN in 2008, it nevertheless supports many of our fabrication needs. We still must make use of other tools in the Nano and Microelectronic fabrication facility at Georgia Tech to complete fabrication, however.

Equipment

Additional photos

View from outside the lab |

Door to the gown room |

Class-100 photolithography room |

a |

Major Laboratory Development Events

-

- 2005-01—2005-12: Design/architecture phase, design/construction phase, contract bidding, contractor selection. Selected contractor: LUWA

- 2005-12-31: Evaporator final test completed at factory site

- 2006-01-16: Demolition

- 2006-01-31: Electrical panel installed

- 2006-02-07: Drywall completed

-

- 2006-02-17: Drop-ceiling grid installed

-

- 2006-02-23: Clean room door installed, anti-static floor installed

-

- 2006-03-03: Clean room entrance completed, exhaust duct installed, class 100 soft-wall clean room set up

- 2006-03-07: Clean room lighting installed

- 2006-03-08: Clean room air handler unit shipped, duct work rerouting (85% inlet filter installed)

- 2006-03-09: Self-powered HEPA fan filter unit installed

- 2006-03-22: Acid and solvent fume hoods installed

- 2006-03-27: Clean room walk-through check up. Punch list made for final certification and sign-off

- 2006-04-06: CEE 100 spin coater installed

- 2006-04-10: Karl Süss MJB-3 contact aligner installed

- 2006-04-18: Anneal Sys AS-One RTA system installed

- 2006-11: TMC optical tables acquisition and installation

- 2007-01: Signatone S250 failure analysis probe station installed

- 2007-02: Keithley SCS-4200 system shipped/installed

- 2007-03: Oriel Cornerstone 260 light source/ monochromator installed

- 2007-03: A prototype 10 ft x 8 ft Faraday cage using shaggy aluminum foils in measurement room — it worked, surprisingly.

- 2007-08: Stanford Research SR830 Lock-in Amplifier acquired

- 2007-08: Demolition of prototype Faraday cage

- 2007-09: 10 ft. x 10 ft. Faraday cage construction completed in measurement room — Thanks to the artistic work of Mr. Richard Turner